Water plays a pivotal role in countless industrial applications. However, its quality can often be compromised by salination and contaminants, posing challenges to your business’s regulation compliances and operational costs. In this blog post, we'll explore what reverse osmosis is, how it can help improve your water purity, and the challenges to consider before making the switch.

What is Reverse Osmosis (RO)?

Reverse Osmosis is a water purification technology that uses a combination of pressure and a semi-permeable membrane to remove impurities from water, including

- Hard Water

- Solid substances

- Ions

- Salinity

- Viruses and bacteria

- Large molecules

Industrial water often harbors contaminants like chemicals, high-salination, heavy metals, and microorganisms. An RO system uses high pressure to push water or other solutions through the semi-permeable membrane, and this membrane blocks particles and molecules larger than water from passing through. This molecular level of filtration leaves you with highly purified water that many other filtration systems cannot match.

Key Advantages of RO in Industrial Water Treatment

While Reverse Osmosis is more complex than carbon-activated filters and other filtration methods, it offers exceptional benefits.

- High Efficiency

- RO systems have exceptional efficiency in removing salts, bacteria, and contaminants, ensuring water quality that meets the rigorous demands of water treatment and industrial processes.

- Customizable

- RO systems can be tailored to meet the unique requirements of your industry, including the size of particles that are allowed through and how the waste is removed from the system line.

- Consistent Quality

- A dependable supply of high-quality water is a must for industries that depend on precise water specifications, and RO delivers just that.

Challenges and Considerations

While Reverse Osmosis is formidable in industrial water treatment processes, there are a few things to consider before you change your current filtration system.

- Maintenance.

Regular maintenance is essential to keep your RO system operating at peak efficiency. This includes routine cleaning and timely replacement of membranes when necessary. Depending on your setup, this could cost more than your current filtration system.

- Energy Consumption.

RO systems require considerable energy to function. Make sure to factor in the associated energy costs during your cost analysis before swapping to an RO system.

- Lower Flow Rate.

More traditional filters tend to allow more water through them. If your industry requires quick treatment of high volumes of water, you should access the space and equipment costs needed for an RO system to keep up with demand.

- Pre-treatment. Depending on the quality of your source water, pre-treatment processes may be necessary to protect RO membranes from fouling and scaling. If you do not already have a pre-treatment system in place, this could increase the initial cost considerably.

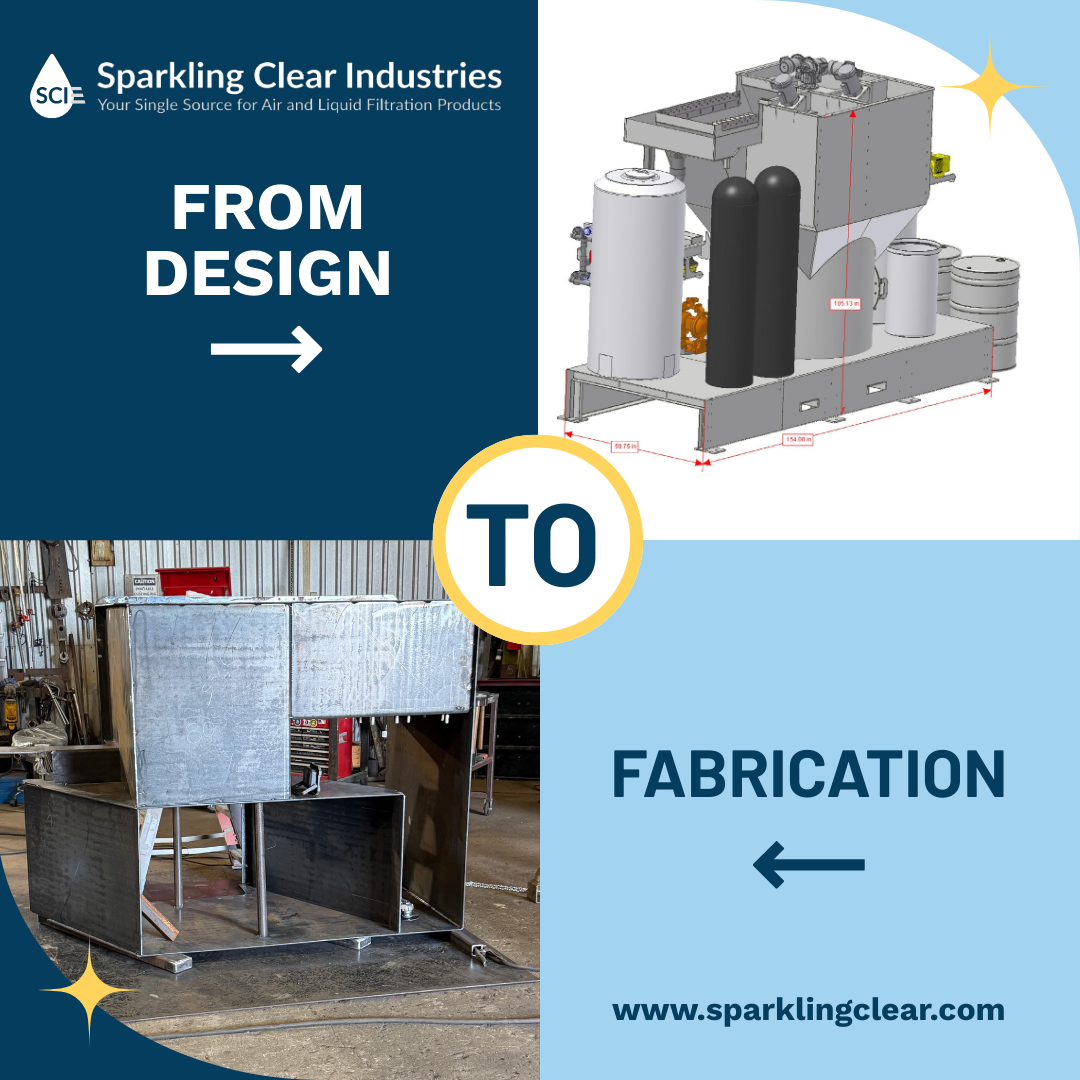

Sparkling Clear Can Help You Find the Best Water Filtration System For your Business

Since 1985 our mission has been and will continue to be doing right by you. Whether you need the best filters for your current system or advice on the best filtration system for your needs, we are committed to helping you balance the cost and efficiency of your filtration system. Contact us today to find your perfect solution.

Share this Post!