What Are The Commercial Uses Of Reverse Osmosis In Texas

November 10, 2022

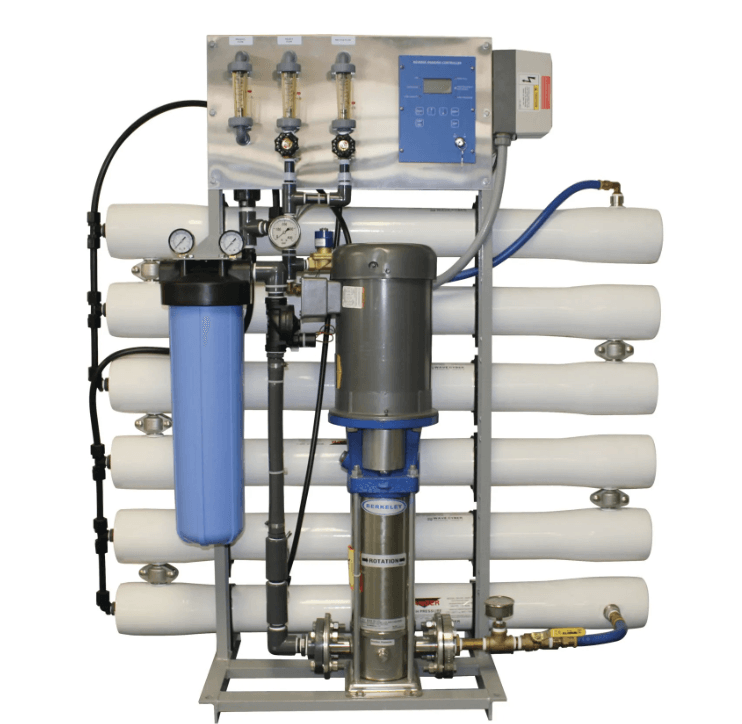

In Houston, TX and along the greater Gulf Coast region, reverse osmosis is typically used in commercial and industrial settings to purify water for drinking, cooking, boiler feed, hydrostatic chloride free testing and other purposes. It can also be used to desalinate water, that is, to remove salt from seawater.

Moreover, reverse osmosis is a relatively simple process that can purify water contaminated with many contaminants, including bacteria, viruses, dissolved solids/salts, and chemicals.

There are many different types of reverse osmosis systems, and the specific system used will depend on the type and concentration of the contaminants that need to be removed.

Reverse osmosis systems can be used to purify fresh water and saltwater. They are often used with other water purification technologies, such as carbon filters, water softeners, and ultraviolet light, to provide clean, safe mineral free water.

What Are The Uses of Reverse Osmosis?

Reverse osmosis is one of the most popular methods for treating water in commercial & industrial settings. It is a good solution for water purification, due to its simplicity, regular flow, and high-quality output.

Here are the common uses for reverse osmosis:

Pharmaceutical Industry

Pharmaceutical production calls for pristine water. Commercial RO's absolute purity makes it so popular in this market. Low TDS and clean, contaminant-free water are constant characteristics of RO water. RO and UV sterilization are frequently combined in this market sector to attain the highest purity.

Agricultural Industry

The American economy significantly depends on agriculture. A commercial reverse osmosis system is advantageous for companies in this sector to utilize for functions such as irrigation & livestock drinking water. In this industry, clean water is essential to ensure food safety regulations are followed.

Production Industry

It is challenging to list all of the commercial uses for RO systems due to the size of the industrial sector.

These systems are vital for even primary businesses like semiconductor production to guarantee the flawless execution of the exact operations required to produce chips and microchips.

Mineral deposits must be thoroughly cleaned and removed with water. It's critical to remember that the chips might lose all of their value if the cleaning fluid contains contaminants.

Healthcare Sector

With the recent difficulties the healthcare industry has faced, access to clean water is crucial to maintaining operations. In this industry, commercial reverse osmosis systems are utilized to keep hospitals, nursing homes, and other healthcare facilities secure, sanitary, and reliable.

Additionally, providing effective sanitization aids in preventing the spread of viruses and infections. This is why the healthcare industry often calls for Houston water treatment companies.

Systems for Heating and Cooling Different Industries

Boiler feed water is probably the largest consumer of RO water as it is vital in keeping the boiler tubes & turbines free from scaling during the heating process.

The proper operation of many different enterprises and organizations depends on cooling systems.

The heat will be swiftly absorbed since RO water comprises purified water and is created by a professional reverse osmosis system.

Since clean water has the potential to absorb heat and remove it from the system, it is crucial for cooling equipment. In many business buildings, clean water is used for heating.

Electrification of Facilities

Electric power plants also need RO water. Utilizing clean water may lower operating expenses and waste from steam pollution. The creation of ideal steam with RO will assist in the generation of power.

The Hospitality Sector

All hospitality-related businesses, including hotels, resorts, cafés, and restaurants, are built on the foundation of pure water. It is used for cooking, drinking, sanitizing, and cleaning. The amount of consumer satisfaction increases with the cleanliness of the water.

Therefore, commercial RO systems are essential for every hospitality-related company, whether a little food truck or a big hotel. It's best to call for Houston water purification!

Industry of Food Production

The food processing sector also needs commercial RO. Pure water is essential for businesses that make frozen goods and craft beer makers.

Conclusion

Commercial reverse osmosis is a process that is used to purify water. This process is used in a variety of industries, including the food and beverage industry, the pharmaceutical industry, chemical processing plants, the semiconductor industry, and many more!

Here at Sparkling Clear Industries, we provide commercial air & water filtration solutions for your team that will improve performance and optimize savings. We are based on the Texas Gulf Coast. Contact us

if you need to get a quote on a system today!

Share this Post!

Production demands can change quickly, especially in chemical manufacturing. Recently, one of our customers on the Houston Ship Channel reached out with an urgent need for increased liquid filtration capacity. Their facility required a multi-round bag filter housing to support higher production rates. Because we maintain rental equipment at our Clute facility, we were able to respond quickly. The 12-round bag filter housing was loaded onto our truck Friday morning and delivered to their facility that same afternoon, helping them move forward without delay. No extended lead times. No waiting on freight. No production bottleneck.

Sparkling Clear Industries is heading to the HASC Tailgate Extravaganza, and we’re looking forward to connecting with industry peers at one of the region’s most anticipated safety-focused events! 📅 Friday, February 6, 2026 🕛 Booths open at 11 AM 📍 Pasadena Fairgrounds The 2026 Tailgate theme, The Golden Age of Safety, is a fitting one. It’s a nod to an era defined by craftsmanship, reliability, and pride in doing things the right way—values that still matter today, especially in industrial environments where safety and uptime go hand in hand. If you’re attending the Tailgate, we invite you to stop by Booth 316. We’ll be happy to talk industrial filtration , reliability, and safety—and grab a steak popper or street taco while you’re there! 🌮 Registration to attend is not required. This free event is open to industry, so bring your colleagues for a day of celebration, safety, and fun! Discover more information here: https://www.hasc.com/tailgate/